Transducers, however, can convert a form of energy into another form while sensors always convert energy into a readable display. Other kinds of transducers measure torque while others communicate air pressure. Read More…

Kistler’s core competence is the development, production and use of sensors for measuring pressure, force, torque and acceleration. Kistler offers a comprehensive range of sensors and systems for engine development, automotive engineering, plastics and metal processing, installation technology and biomechanics.

Since 1971, Thermalogic has been a leading manufacturer of electronic temperature and humidity control and sensors. Here at Thermalogic we work with our clients in a partnership to build a lasting business relationship. All of our products have quick turnaround times, including custom designs, and are thoroughly tested prior to being sent out. At Thermalogic we pride ourselves on our high...

More Temperature Transducer Manufacturers

Temperature transducers translate energy from pressure or from the temperature itself and use it to produce a measurement, displayed on a gauge, dial or display. These devices take temperature readings by either coming into direct contact with a substance or by evaluating its infrared energy. Depending on the kind, temperature transmitters can be housed in a tough stainless steel enclosure and equipped in cooling jackets or air purge assemblies; they are built to withstand the most intense industrial conditions.

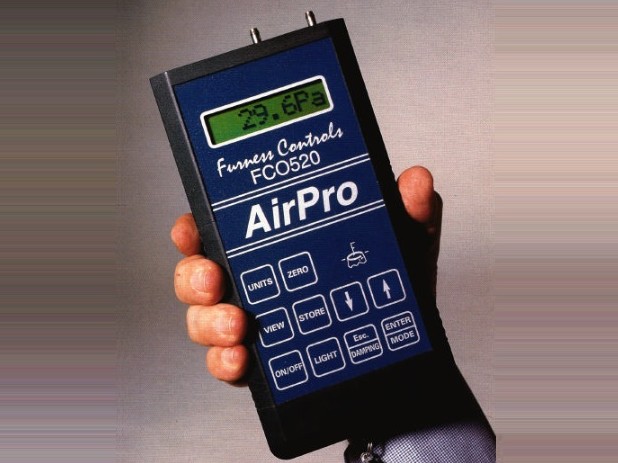

Transducers in the form of probes have no moving parts that would require maintenance and often consist of two thin metal wires or a flat disc. Other kinds are handheld and encased in plastic. They have a small window that allows the internal sensors to make a reading of infrared energy. Temperature transducers and sensors are used in many industries and processes where heat is present.

Typical applications include measuring the temperatures of ceramic materials, metals, plastics, robotics, semiconductors, textiles and glass. Processes like heat treating, printing and petrochemical development are just a few examples of operations in which temperature transducers are useful.

There are two main ways that a temperature transducer or transmitter measures thermal energy. Contact temperature transducers physically touch the substance and then measure their own temperature. When thermal equilibrium is achieved, there is no heat flow between the transducer and the substance being measured; the temperatures are the same. They are fairly durable and simple to use. However, the physical contact may contaminate the substance or damage the transducer. Readings require time because thermal equilibrium must be reached.

Also, there is an increased potential for incorrect measurements when using contact transducers because it is difficult to accurately measure a flowing liquid. Regardless, they are used to measure solids, liquids and gases. The alternative is to use a non-contact transducer. These devices read temperature by measuring the infrared energy being emitted by an object or substance.

Though they cannot measure gas temperature, they are used with solids and liquids. Non-contact transmitters are used to measure temperature when actual contact between the sensor and product would cause contamination or corrosion, when the substance is moving, when the reading must be taken quickly or when the reading must be taken through a window (such as in an explosive environment).

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services