Air Pressure Sensors

Air pressure sensors measure the force of air as exerted on the device and then convert the information into a readable display. Transducers are similar; they are designed to convert one form of energy into another, while sensors are explicitly intended to measure and provide a reading of the measurement. Sensors are often composed of transducers, so the terms are sometimes used interchangeably. Read More…

GP:50 manufactures pressure transducers & transmitters: industrial, differential, oil & gas, automotive test stand, aerospace, military, high temp. plastics, low-cost OEM, flush diaphragm & sanitary, cryogenic & high temp., and water treatment. Plus, level & temperature transmitters & transducers.

NOSHOK is a manufacturer of pressure transducers: heavy-duty, explosion-proof, non-incendive, intrinsically safe, hall effect, high-accuracy heavy-duty with serial interface, high-volume OEM, thick film sensor and miniature pressure transducers. We have other instrumentation as well.

We are proud to offer a wide variety of sensors. We offer photoelectrics such as high temperature photoelectric sensors. We also offer inductive sensors such as high temperature inductive sensors. In the area of capacitive sensors we offer mini capacitive sensors in addition to many other types. We go that extra mile to provide for all your sensor needs.

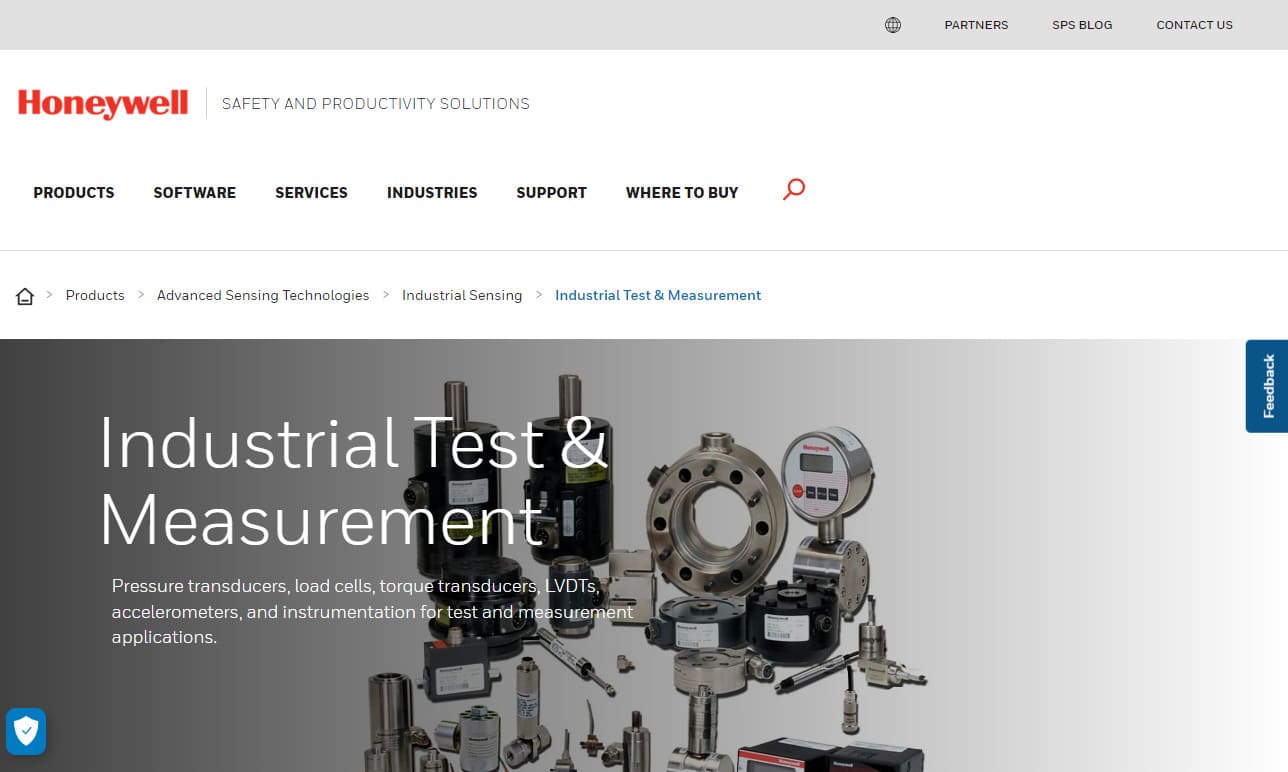

Honeywell offers a broad portfolio of pressure transducers for test and measurement in industrial, automotive/transportation, aerospace, and medical applications Honeywell’s pressure transducers are suited for both high and low temperatures. Products include strain gauge pressure transducers, differential pressure transducers, LVDTs and miniature pressure transducers. Customization is available ...

More Air Pressure Sensor Manufacturers

They are frequently encased in stainless steel and found in nozzles or connectors, although separate electronic instruments are common as well. Air pressure sensors are important because an incorrect pressure can cause injury to nearby personnel or damage surrounding materials and equipment. If a mechanic is unsure how much pressure is in a tire, for example, he could overfill it and cause it to burst, or he could under-fill it and cause excessive wear to the car. Air pressure sensors are used to monitor pneumatic air pressure in heating, ventilation and air conditioning systems, pneumatic compressors, gas cylinders and other systems that rely on maintaining certain pressure levels. They are also useful for determining the air pressure of a given room, because air flows from areas of high pressure to areas of low pressure. Hospitals monitor air pressure to minimize the risk of spreading infection and disease.

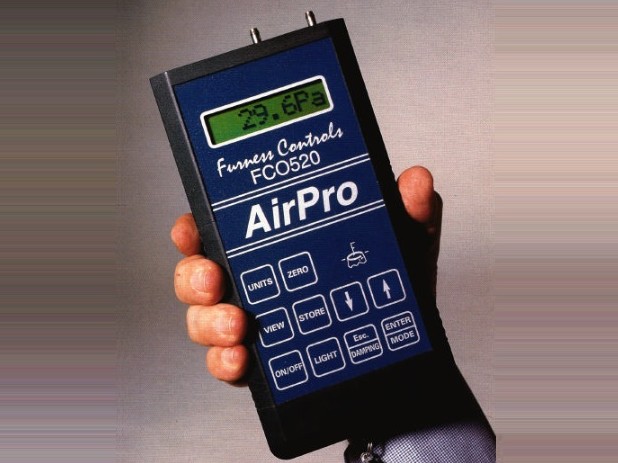

Air pressure sensors are small enough to fit in an open hand; some are the size of a fingernail. They rely on the use of a silicon chip, also called an integrated circuit. The pressure of the air bends the chip according to how much force is being exerted. The bend causes the charge in the integrated circuit to change, which the sensor detects and uses to determine the air pressure. It transmits the information to a gauge or display.

Some sensors have audible alarms to alert the operator that the pressure is either too high or too low, while other systems, such as those found in cars, have a light to inform the driver if tire pressure is incorrect. Air pressure sensors are sometimes combined with other useful devices such as pressure regulators and calibrators. Pressure regulators control the amount of pressure running through a system and can be altered to increase or reduce the pressure based on the reading the sensor provides.

Calibrators are used to determine if the sensor is making accurate readings. These instruments receive input from the system and compare that with the reading on the sensor to make sure that everything is functioning correctly and accurately. It is a safety hazard if air pressure is unregulated or misread.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services