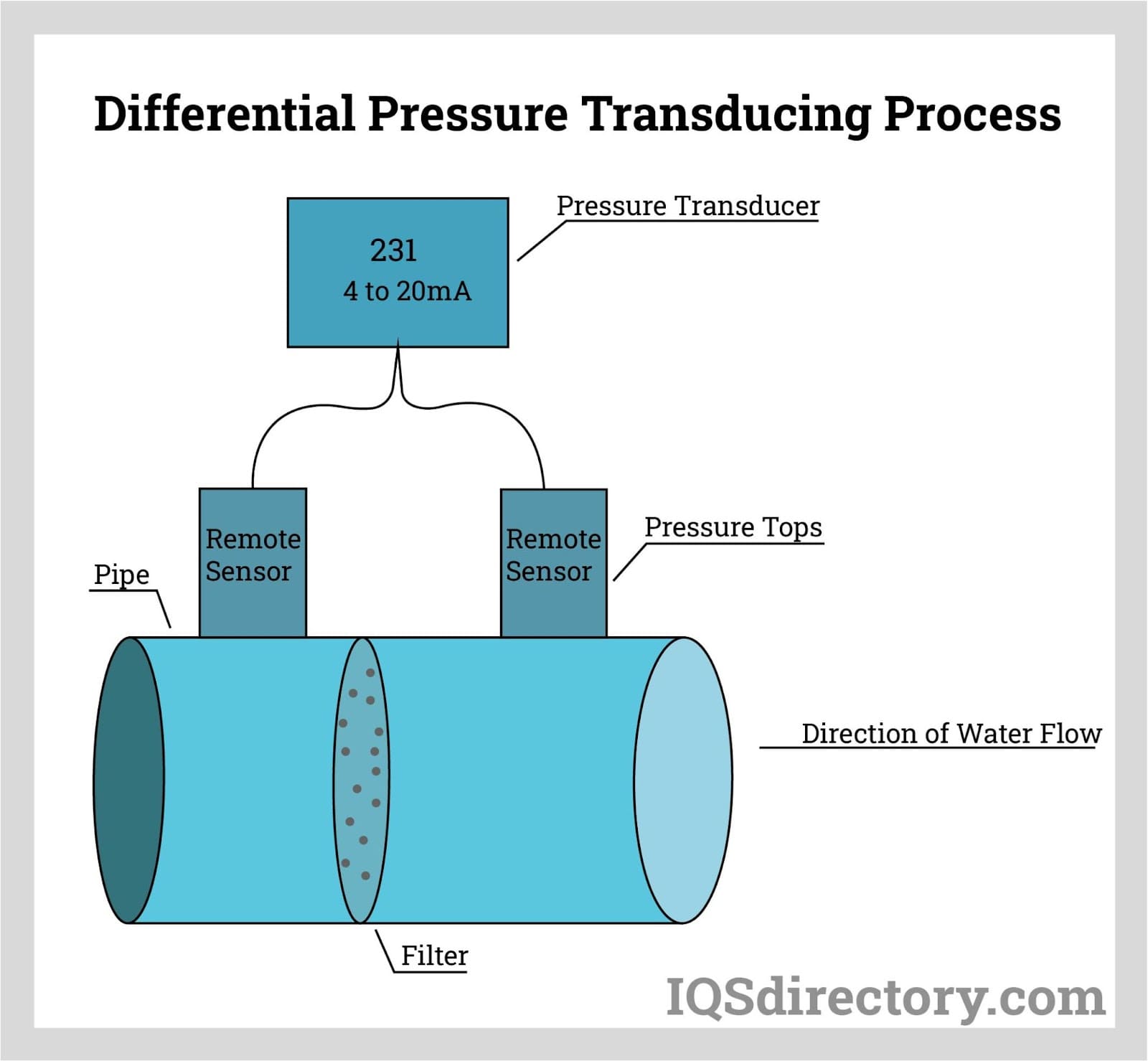

Differential pressure transducers determine the pressure difference between two points. The performance of a filter inside a system can be continuously monitored with a differential pressure transducer. An operator can see the state of the filter in real time by using a differential pressure transducer and the output signal from the pressure transducer. As a result, the system will only need to be shut down periodically for examination. Because it avoids potential compounded inaccuracies and the requirement to calculate the difference between two transducers, using a differential pressure transducer is advised over using two individual pressure transducers. Read More…

GP:50 manufactures pressure transducers & transmitters: industrial, differential, oil & gas, automotive test stand, aerospace, military, high temp. plastics, low-cost OEM, flush diaphragm & sanitary, cryogenic & high temp., and water treatment. Plus, level & temperature transmitters & transducers.

NOSHOK is a manufacturer of pressure transducers: heavy-duty, explosion-proof, non-incendive, intrinsically safe, hall effect, high-accuracy heavy-duty with serial interface, high-volume OEM, thick film sensor and miniature pressure transducers. We have other instrumentation as well.

We are proud to offer a wide variety of sensors. We offer photoelectrics such as high temperature photoelectric sensors. We also offer inductive sensors such as high temperature inductive sensors. In the area of capacitive sensors we offer mini capacitive sensors in addition to many other types. We go that extra mile to provide for all your sensor needs.

Honeywell offers a broad portfolio of pressure transducers for test and measurement in industrial, automotive/transportation, aerospace, and medical applications Honeywell’s pressure transducers are suited for both high and low temperatures. Products include strain gauge pressure transducers, differential pressure transducers, LVDTs and miniature pressure transducers. Customization is available ...

More Differential Pressure Transducer Manufacturers

A piezo-resistive or thin-film pressure sensor serves as the pressure transducer. This gadget features a pressure sensor and a device body connected by an electrical circuit. The pressure sensor converts the physical pressure change it detects into an electronic value that may be used in calculations. The pressure transducer transforms only a physical pressure measurement into an electrically readable value. The transducer does not standardize or compensate for pressure measurements.

Types of Differential Pressure Transducers

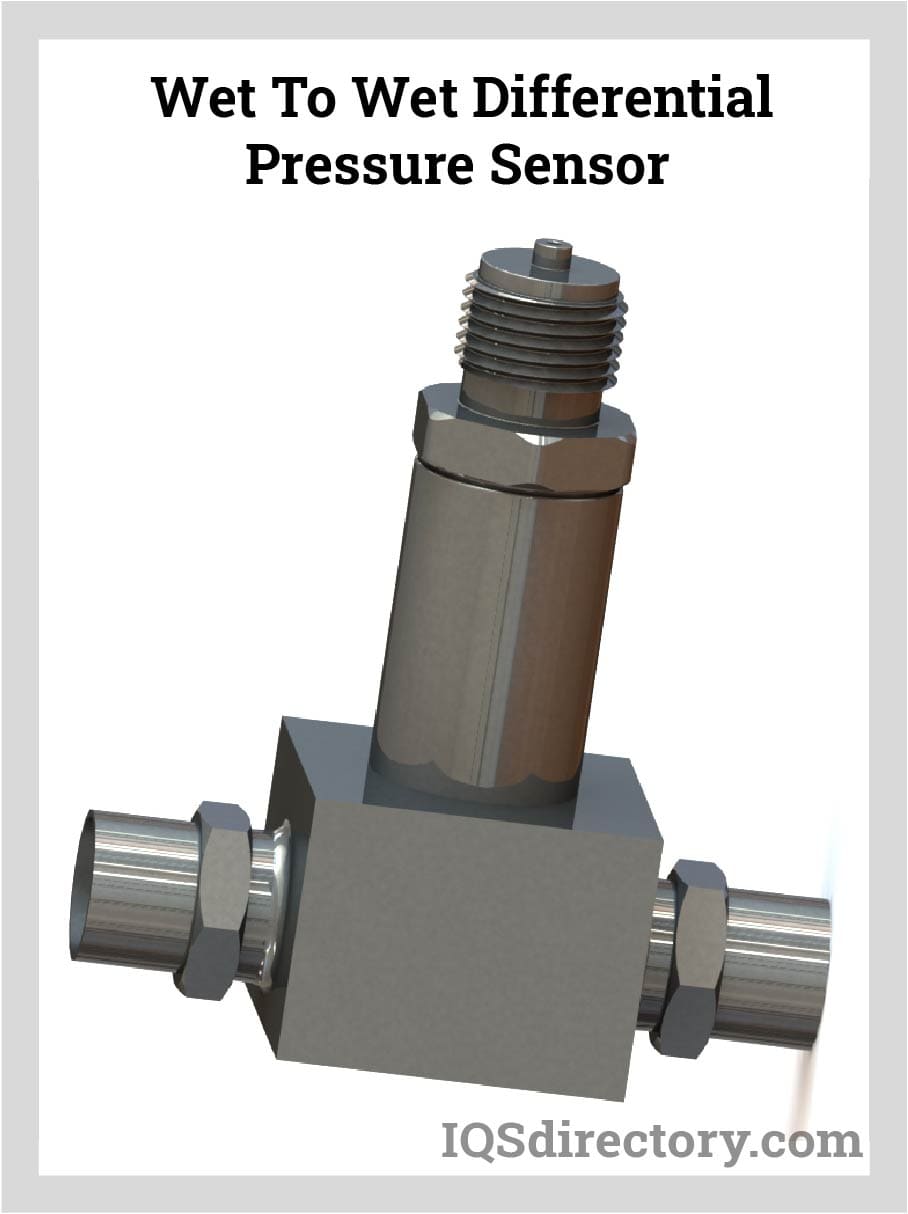

Wet-to-Wet Transducers

A wet-to-wet differential pressure transducer is employed when taking the appropriate measurement with a liquid on both the high and low-pressure ports. An electrical signal, often a voltage or current output, is created by linearizing the pressure difference between the high and low-pressure ports. The differential pressure for these sensors can be calculated using two independent sensors or a single diaphragm with fluid pushing on both sides of the transducer.

Application of Wet-to-Wet Transducers

Wet-to-wet transducers are frequently employed in HVAC applications for building management, including filter status, strainer basket monitoring, chiller efficiency, and pump suction and discharge. Additionally, these sensors are utilized in pressure tanks and industrial applications.

Wet-to-Dry Transducers

At the wet port, where fluid can be applied, a wet-to-dry differential pressure transducer has a single metal wet-diaphragm. The dry port exposes the internal circuitry to the medium, and only pure dry gas should be applied to it because it has an open electrode. The quantity of airflow that causes the diaphragm to move against the water flow is used to calculate pressure. It is crucial to remember that water cannot be utilized in the dry port or on both sides.

Dry-to-Dry Transducers

A dry-to-dry differential pressure transducer is used in applications where the key measurement is carried out using air or a non-corrosive gas on both the high and low-pressure ports, similar to a wet-to-wet transducer. The pressure differential between the high and low-pressure ports is linearized to produce an electrical signal, frequently a voltage or current output. These sensors are constructed from a single diaphragm that deflects in one of two directions. The result is linearized to give an electrical output similar to the wet-to-wet differential transducer.

Application of Dry-to-Dry Transducers

For low monitoring pressure of less than 3 PSI, a dry-to-dry transducer is more frequently employed. However, high-pressure Test & Measurement applications can also use the sensor design. Dry-to-dry transducers are frequently utilized in clean rooms, isolation rooms, filter status, leak detection, and stairwell pressurization.

How the Transducer Works

- Line pressure, also known as upstream pressure, travels to the system's filter. The upstream pressure can flow to the high side of the differential pressure transducer thanks to a pipe fitted as a pre-filter.

- The filter allows media to pass through while removing any impurities.

- The system continues to be filled with the post-filter downstream pressure. The downstream pressure can flow to the low side of the differential pressure transducer thanks to a pipe installed post-filter.

- As impurities are eliminated over time, the filter will eventually become clogged. As a result, the downstream pressure will drop, increasing the difference between P1 and P2. The transducer's linear output signal will grow as the difference does.

Advantages of Differential Pressure Transducers

- They are reasonably priced and built using durable technologies.

- They offer excellent output regulation and stability.

- They are relatively small, very sensitive, and lightweight.

- All types are easy to build and quite robust.

- They have outstanding stability.

- They have numerous electrical connections, output ports, and pressure ports.

Disadvantages of Differential Pressure Transducers

- They provide merely fair accuracy when there are drifts.

- They give a delayed reaction to vibrations and shocks.

- They provide just fair accuracy and are unreliable for high-temperature ranges.

- They are extremely susceptible to external factors.

Choosing the Proper Differential Pressure Transducer Manufacturer

To make sure you have the most productive outcome when purchasing differential pressure transducers from a differential pressure transducer manufacturer, it is important to compare at least 4 companies using our list of differential pressure transducer manufacturers. Each differential pressure transducer manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each differential pressure transducer company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple differential pressure transducer companies with the same quote.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services