Transmitters are also called sensors or transducers; they both convert signals into a reading of pressure or temperature. There are two main ways level transmitters receive information: by making point level or continuous level readings. Read More…

GP:50 manufactures pressure transducers & transmitters: industrial, differential, oil & gas, automotive test stand, aerospace, military, high temp. plastics, low-cost OEM, flush diaphragm & sanitary, cryogenic & high temp., and water treatment. Plus, level & temperature transmitters & transducers.

NOSHOK is a manufacturer of pressure transducers: heavy-duty, explosion-proof, non-incendive, intrinsically safe, hall effect, high-accuracy heavy-duty with serial interface, high-volume OEM, thick film sensor and miniature pressure transducers. We have other instrumentation as well.

We are proud to offer a wide variety of sensors. We offer photoelectrics such as high temperature photoelectric sensors. We also offer inductive sensors such as high temperature inductive sensors. In the area of capacitive sensors we offer mini capacitive sensors in addition to many other types. We go that extra mile to provide for all your sensor needs.

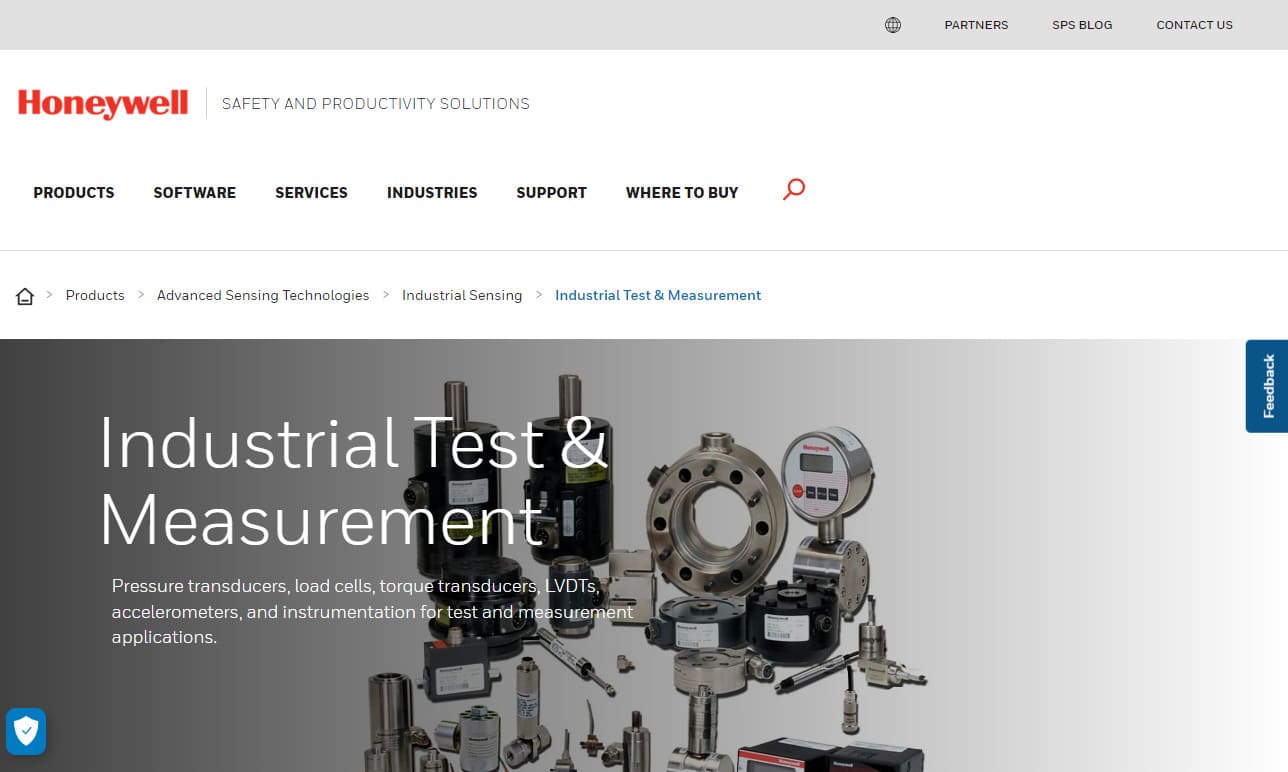

Honeywell offers a broad portfolio of pressure transducers for test and measurement in industrial, automotive/transportation, aerospace, and medical applications Honeywell’s pressure transducers are suited for both high and low temperatures. Products include strain gauge pressure transducers, differential pressure transducers, LVDTs and miniature pressure transducers. Customization is available ...

More Level Transmitter Manufacturers

Of the two types of information receiving styles employed by level transmitters, point level transmitters sense when a substance has reached a predetermined level, usually providing an alarm or electrical charge that shuts off the feed. Continuous level transmitters are made up of multiple sensors that provide a constant reading of the level of the substance. These transmitters are small and usually encased in stainless steel for protection because level transmitters are built to withstand a wide range of temperatures, pressures, substances and conditions in the specified space.

This space can be a vat, tank, silo or other container used for mixing, processing or other operations. The transmitters perform an important task because they take measurements where people cannot, like in an enclosed tank or a vat of chemicals with a mixing blade. Knowing how much material is in a container is valuable across many industries because over or under-filling a specified space can lead to hazardous conditions as well as loss of product and time.

Level transmitters use many different methods and technologies to measure the levels of substances. These sensors are unaffected by changes in conductivity, temperature, pressure, humidity or moisture content as well as dust and static-charge buildup. There are five main kinds: non-contacting radar, guided wave radar, ultrasonic, differential pressure and vibrating fork. Non-contacting radar transmitters typically are installed on top of a container, so the waves are sent downward into the enclosure.

The transmitter uses the returning echoes to determine how much substance is in the tank. Guided wave radar transmitters are able to provide both level and interface measurements because the advanced technology can differentiate between different layers of fluids, such as oil and water. Ultrasonic level transmitters have non-contacting sensors housed in watertight enclosures. They use ultrasonic waves to gather information. Differential pressure level transmitters take multiple readings in different places in the container and compare the readings to determine the level.

Vibrating fork transmitters are used with fine powders and granular solids. Multiple tines are lowered down toward the powder and stop when they reach the top of it. They vibrate to minimize material buildup between the probes. Other styles include optical level transmitters, air bubblers and rotation paddle level transmitters.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services